Clean rooms are an integral part of many industries in Israel, including electronics, biotechnology, pharmaceuticals, and food production. With the growing demand for uncompromising quality and strict adherence to manufacturing standards, clean rooms provide a controlled environment where contamination levels, temperature, and humidity can be precisely regulated. This article explores the main applications of clean rooms in Israeli industry, the advanced technologies that drive them, and their contribution to innovation and the development of the local economy.

What is a Clean Room?

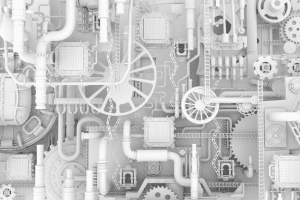

A clean room is a controlled environment designed to prevent the entry of external contaminants and maintain a low level of harmful particles in the air. Key features of clean rooms include:

-

Air Filtration System (HEPA): Filters that reduce microscopic particles.

-

Temperature and Humidity Control: Maintaining stable conditions essential for sensitive processes.

-

Special Materials: Use of walls, floors, and clothing that do not emit particles.

-

Access Control: Restricted entry and sanitation protocols to prevent external contamination.

Key Industries Using Clean Rooms in Israel

Electronics and Semiconductors:

Israel’s electronics industry relies on clean rooms for manufacturing chips and printed circuit boards. High precision is required to avoid disruptions in the production process.

Biotechnology and Pharmaceuticals:

The production of medications, vaccines, and biological cells requires a completely sterile environment. Clean rooms allow manufacturers to comply with GMP (Good Manufacturing Practice) standards.

Food Industry:

The production of sensitive products such as infant formula and beverages demands a contaminant-free environment. Clean rooms ensure compliance with strict safety standards.

Optics and Medical Devices:

The development and manufacturing of medical equipment such as microscopic lenses, laser systems, and surgical tools require exceptional cleanliness and precision.

Advanced Clean Room Technologies

-

Smart Air Control Systems:

AI-based technologies for real-time monitoring and management of air quality. -

Advanced Sensors:

Continuous monitoring of parameters such as temperature, humidity, and particle concentration. -

Robotics and Automation:

Robots for cleaning, assembly, and product transport without human contact, reducing contamination risks. -

Advanced Materials:

Development of durable, low-emission materials for use in clean room walls, ceilings, and floors.

Standards and Regulation

Industries that utilize clean rooms must comply with international standards such as ISO 14644 and GMP regulations. In Israel, the Standards Institution of Israel provides guidance and support for meeting these requirements. Strict regulation ensures that manufacturing processes meet high quality requirements while preventing defects in final products.

Challenges in Using Clean Rooms

-

High Setup and Maintenance Costs:

Constructing a clean room requires significant upfront investment, including advanced systems and ongoing maintenance. -

Skilled Workforce Shortage:

Operating and maintaining clean rooms requires dedicated training and expertise. -

Technological Innovation:

Industries must stay up to date with new technologies to remain competitive in the global market.

Benefits to the Israeli Economy

Clean rooms not only support advanced industries but also strengthen Israel’s position as a global innovation hub. These industries create jobs, attract foreign investment, and contribute to the export of high-tech products and services.

Conclusion

The use of clean rooms in Israeli industry continues to grow, forming a critical component in advanced manufacturing processes. With cutting-edge technology, strict regulation, and ongoing development, clean rooms position Israel at the forefront of global innovation. Continued investment in this area is expected to yield significant technological and economic benefits in the future.