The Guide to Building Cleanrooms in Sensitive Industries

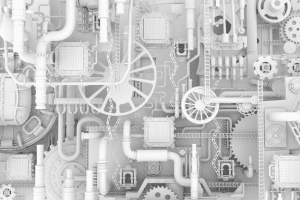

Cleanrooms are a cornerstone of industries that require manufacturing under strict, controlled conditions. They provide a sterile environment that prevents the intrusion of even the tiniest contaminants — particles that could compromise the production or inspection of highly sensitive products. From microchip manufacturing to pharmaceutical production, a cleanroom is essential for ensuring quality, precision, and regulatory compliance.

In this article, we’ll explore the key construction stages, primary requirements, and the significant value cleanrooms offer to modern businesses.

Why Do You Need a Cleanroom?

In advanced industries, even the smallest error — such as a single dust particle — can cause substantial damage. A cleanroom enables production and quality control in a precisely monitored environment, maintaining parameters like airborne particle levels, humidity, temperature, and pressure. These ensure product integrity from development to delivery.

How to Build a Cleanroom – Step by Step

1. Planning and Needs Assessment

The first step involves creating a detailed work plan:

What is the cleanroom’s purpose? What are the industry-specific requirements? What cleanliness level is needed?

This phase also defines the location, space, and necessary equipment — all in compliance with international standards like ISO 14644.

2. Choosing Materials and Support Systems

In cleanrooms, there is no room for compromise — only materials that are easy to clean and do not emit particles are selected. Supporting systems include high-efficiency air filtration (HEPA/ULPA), humidity and temperature control, and specialized lighting that does not interfere with the controlled environment.

3. Construction and Installation

This is where the physical space is built — including walls, ceilings, floors, and all technical systems. Precision is key, with full sealing required to prevent contamination. It is crucial that the work is carried out by contractors experienced in cleanroom construction.

4. Final Testing and Certification

Once construction is complete, comprehensive tests are conducted: airflow analysis, particle counts, temperature and humidity control. Only when all conditions meet the required standards is the cleanroom approved for use.

What Does Your Business Gain?

Uncompromising Quality

Cleanrooms significantly improve product quality thanks to a contaminant-free environment. Industries such as electronics, biotech, and pharma benefit from reduced failure rates and lower production costs.

International Regulatory Compliance

Operating within cleanrooms provides a competitive advantage, as it ensures compliance with strict global regulatory standards, streamlining product approval, marketing, and export.

Improved Operational Efficiency

A controlled environment enhances production efficiency and reduces errors — meaning fewer stoppages, less rework, and more time for innovation and development.

In Summary – A Smart Investment

Building a cleanroom requires careful planning, technical expertise, and collaboration with experienced professionals.

But the investment pays off: your business gains access to an advanced production environment that meets the highest standards, enhances performance, and enables success in competitive markets.