Cleanrooms in Israeli Industry: Strict Standards, Competitive Advantage

The modern industrial world operates under increasingly stringent quality, safety, and precision requirements. One of the key ways to ensure the cleanliness, sterility, and accuracy needed in advanced manufacturing is through the use of cleanrooms. As a global leader in technology and biotechnology, Israel is at the forefront of cleanroom use across industries such as electronics, pharmaceuticals, biotech, cosmetics, and food production.

What Is a Cleanroom?

A cleanroom is a controlled industrial environment where the levels of dust, microscopic particles, and contaminants are tightly regulated — far beyond the conditions of regular ambient air. It features filtration systems, humidity and temperature control, and pressure management, and is designed for highly sensitive processes.

Why Are Cleanrooms Needed?

1. Contamination Prevention

In sectors like pharmaceuticals, biotechnology, and food, even tiny contaminants can harm products or pose health risks. Cleanrooms ensure a sterile production environment.

2. Maximum Precision

In microchip manufacturing, even a nanometer-sized dust particle can ruin an electronic board. Cleanrooms enable precise, safe, and efficient production.

3. Regulatory Compliance

Many sectors are required to meet standards like ISO 14644 or Ministry of Health regulations. Without a certified cleanroom, licenses and approvals are unattainable.

4. Competitive Advantage

A facility with certified cleanrooms is seen as leading, innovative, and high-standard — offering a true marketing edge.

Key Industries Using Cleanrooms in Israel

-

High-tech and Semiconductor Industry: Companies like Intel, Tower Semiconductor, and others operate under strict sterile conditions.

-

Pharmaceutical and Biotech: Firms like Teva, Kamada, and Pluristem.

-

Academic Research Laboratories: Institutions specializing in nanotechnology and biology.

-

Cosmetics and Medical Food Production: Manufacturers must comply with GMP and sterile production standards.

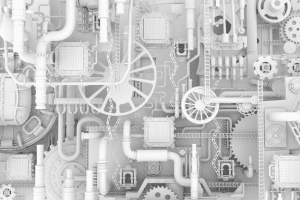

What Does a Cleanroom Look Like?

-

Smooth, crack-free walls and ceilings to prevent dust accumulation

-

Antistatic flooring, always clean

-

HEPA/ULPA air filtration systems that remove up to 99.999% of particles

-

Sterile clothing for workers – including gloves, shoe covers, and masks

-

Entry through an air shower to remove particles from garments

Cleanroom Classifications by Standard

-

ISO Class 1 – Highest level of cleanliness (fewer than 10 particles per cubic meter)

-

ISO Classes 5–7 – Common in pharma, biotech, and semiconductor industries

-

GMP Grades A–D – Based on European pharmaceutical regulations

Costs and Setup

Building a cleanroom requires meticulous planning, customized architecture, and dedicated equipment.

Costs vary by classification, but it’s an investment that pays off in reliability, precision, and high-quality output.

Ongoing maintenance, periodic particle testing, and staff training are also required.

Future Trends

In Israel and globally, there’s a clear trend toward full automation inside cleanrooms.

Robots are replacing human operators, smart cameras monitor cleanliness, and remote control systems handle environmental oversight — all of which reduce contamination risks and improve efficiency.

Conclusion

Cleanrooms are not just a regulatory requirement — they are an investment in quality, safety, and a company’s reputation.

For anyone operating in sensitive industries in Israel, a cleanroom is a critical foundation for business success, legal compliance, and global competitiveness.

As technology evolves, a sterile production environment is no longer optional — it’s the new standard.